Seed germination and seedling uniformity in most greenhouses appear to be quite good. In some of the earlier seeded greenhouses, a preventive application of Senator 70WP fungicide has already been made for the control of Rhizoctonia Damping-off. The application is made when the larger leaves of the seedlings are about 1.5 cm in diameter (dime-sized) or at the first sign of disease.

Chilling Injury

Some growers have expressed concerns over chilling injury to their greenhouse seedlings and whether the injury will affect the growth of these plants in the field.

Some of the initial symptoms of chilling injury are a bright yellow colour in the growing point of the seedling and upward cupping of the leaves. As the seedlings become larger and the leaves grow out, some leaves will be malformed, cupped and have a distinct yellow/white discolouration.

Seedlings will outgrow chilling injury in the greenhouse without any ill-effects on the seedlings when they are transplanted to the field.

Chilling injury is caused by exposure of the seedlings to a large variation in air temperature in the greenhouse. An example of how this can occur is when a greenhouse is being ventilated on a very cool but sunny day. If it is windy outside, the temperature drop will be enhanced when a ridge or side vent is open on the windward side. Also, some varieties can be more susceptible than others to chilling injury.

Effects of Algae

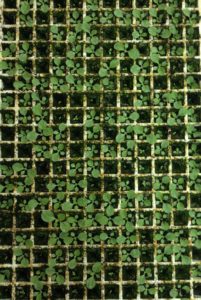

On some farms this year we have seen where algae in trays has affected the emergence and early growth of some of the seedlings. Slower growing seedlings affected by algae will sometimes only reach the 2 leaf stage and turn brown and die. Seedlings that do not die tend to remain small and eventually become shaded out by the seedlings that are growing normally.

There are no chemical treatments for algae in tobacco greenhouses. Conditions that are optimum in the greenhouse for rapid seed germination and early seedling growth help seedlings to outpace the algae so that the seedlings become large enough that the algae can no longer affect them. Not fertilizing for 2 or 3 weeks after seeding can also help to prevent an early buildup of algae in trays.

Disinfecting trays with steam prior to use will help to reduce algae in trays at the time of seed germination and seedling emergence. Tray steaming also helps to control diseases, such as Black Root Rot, that can be harmful to tobacco.

Further information about algae and measures to reduce its effect on seedlings can be found in a technical bulletin in the plant protection area of this website.

Injury from Heat and Dryness

Abnormally warm and sunny conditions from April 16-18 appears to have been partly responsible for some leaf injury to seedlings in some dry tray greenhouses. In these cases, the moisture content of the media was also likely on the dry side at some point while conditions were warm and sunny. The older leaves of the seedlings collapsed and turned brown, however, the growing point appears not to have been injured and is still active. These seedlings should recover normally. It should be noted that in the photo below, the seedlings are also in need of additional nitrogen.

Field Soil Fumigation

It’s that time of year again when it will not be too long before soil fumigation occurs. Appropriate soil moisture is important for the fumigant to be effective. Conditions that are too dry can result in an unsafe release of the fumigant from the soil and poor control of soil pathogens, such as nematodes.

The product label for the soil fumigant that will be used provides information on soil moisture conditions required at the time of application. For chloropicrin based products (Chloropicrin 100 and Pic Plus Fumigant), if there is less than 50% available water capacity 20 cm below the surface, the soil moisture must be adjusted. For metam sodium based products (Busan 1020 and 1236, and Vapam HL), the soil moisture in the top 15 cm must be between 60% to 80% of available water capacity, otherwise the soil moisture must be adjusted.

The product label for the soil fumigant being used will provide information on how to determine soil moisture using the USDA Feel and Appearance Method. An instrument, such as a tensiometer, can also be used. Irrigation prior to fumigation or waiting until there is sufficient rainfall will be necessary in situations where a tilled soil is found to be too dry for fumigant application.

Post prepared and sent by Canadian Tobacco Research Foundation

Mailing Address: CTRF, P.O. Box 322, Tillsonburg, ON N4G 4H5

Telephone: 519-842-8997

Web Address: http://ctrf1.com